From workshop floor to factory line: A footwear unit takes shape in Agra district

Zeba Rani, a resident of Shamsabad in Agra district, grew up around the routines of footwear work.

Her father has spent about 25 years in the shoe line, moving between factory production and trading, and those daily processes formed the backdrop of her childhood. She watched cutting, fitting, finishing and packing not as a business plan but as regular work, learning informally how footwear moved from raw leather to a finished product.

That familiarity became more structured when she later joined an ODOP centre, where she received training focused on leather and shoe manufacturing. There, she learned about different types of leather, the sequence of manufacturing steps, the machines required at each stage, and how those machines were operated and maintained.

The training gave direction to what had earlier been scattered observations, and it helped her understand what would be required to run a unit independently.

Turning experience into a unit

After the training, Rani began considering starting something of her own. The decision was not abrupt. Her father’s existing business provided practical support and guidance, and she already had clarity on machinery, sourcing and basic production planning.

Financial support, however, was necessary to move beyond small trading activity into manufacturing.

She applied for assistance under the Mukhyamantri Yuva Udyami Vikas Abhiyan (CM YUVA) Yojana through the ODOP channel. The loan was sanctioned, and she used it to set up her footwear manufacturing unit.

Earlier, production had been limited and largely trade-based, but with the new setup, she began manufacturing at a larger scale. Orders began to move beyond the local market, and footwear produced at the unit started reaching buyers outside the immediate area.

Changes in work and daily life

The shift to manufacturing altered both work routines and household stability. With production increasing, income became more predictable, and the unit began employing four to five workers regularly.

Tasks were divided step by step: cutting, fitting, bottom work, finishing, passing, and packing, with each worker assigned a specific role. Rani oversees the distribution of work, checks the finishing quality and ensures that output meets expected standards.

Her role is largely managerial and supervisory, coordinating between workers and ensuring the process runs smoothly. Support from her family remains central — her father continues to advise based on long experience, and her brothers are involved in operations, making it a family-run enterprise in practice.

Looking ahead, she hopes to expand sales further beyond Agra and develop the unit into a recognisable brand over time. For now, the focus remains on steady production, reliable quality and gradual growth under CM Yuva Yojana support.

Reflecting on the journey, she says, “We used to only watch the work earlier;, now I have learned to manage it myself.” The shift from observation to responsibility has brought a sense of stability, grounded in familiar work and careful expansion rather than sudden change.

You May Also Like

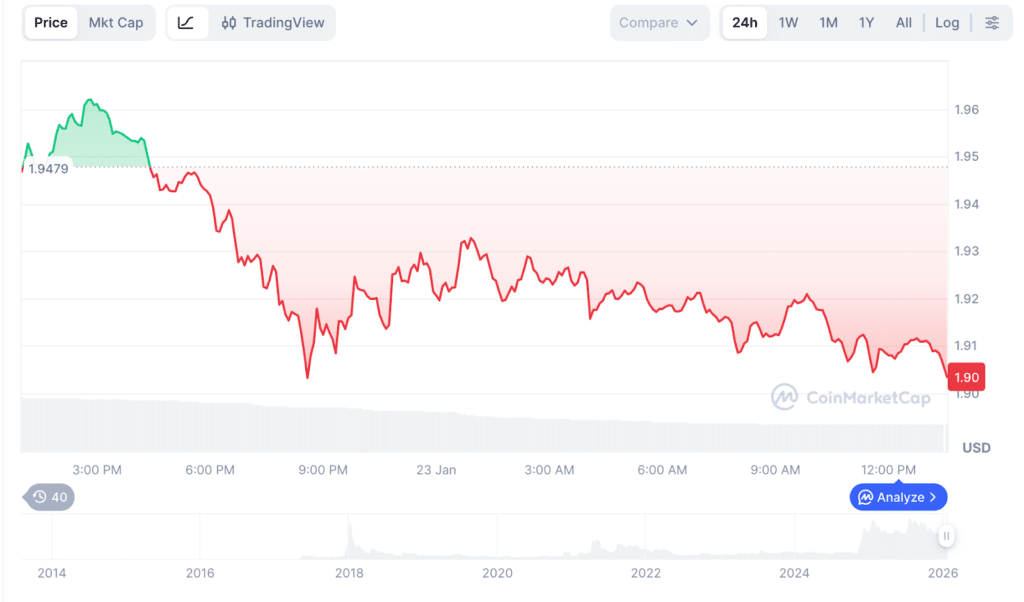

Botanix launches stBTC to deliver Bitcoin-native yield

XLM Price Prediction: Targets $0.25-$0.27 by February 2026